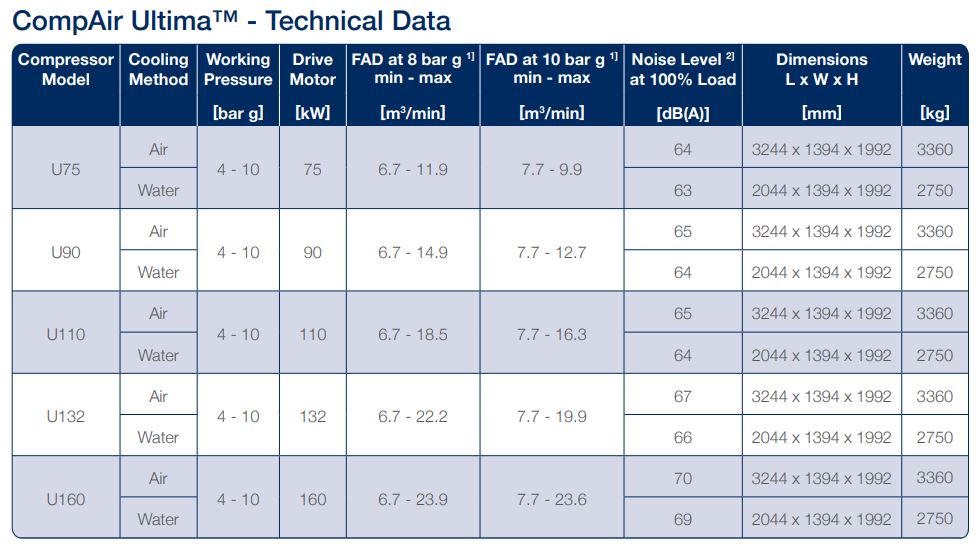

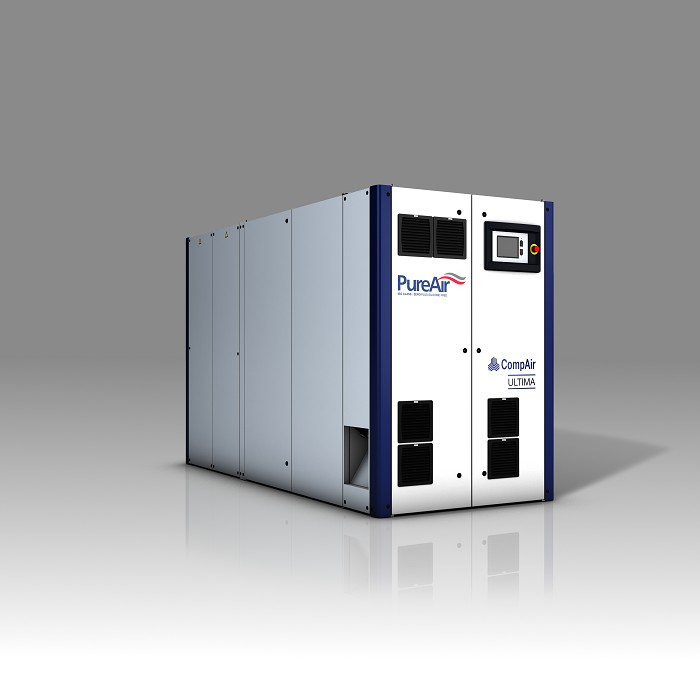

CompAir Ultima U75-U160

100% oil and silicone-free for clean air critical applications

Ultima™ is CompAir’s groundbreaking oil-free PureAir screw compressor with a unique design. It is a brand new compressor range and it utilises a low pressure and high pressure dry screw airend. Each airend is individually driven by a variable speed, permanent magnet synchronous motor, offering exceptional levels of efficiency versus traditional oil-free technology.

CompAir is always improving the best products to be even better and more cutting edge.

Why Choose Ultima™?

The unique patented design delivers numerous benefits to compressed air users:

Unrivalled Energy Efficiency

The Ultima’s advanced 2-stage airend design and high-speed permanent magnet (PM) motors deliver best-in-class efficiency, exceeding IE5 and IES2 standards—significantly lowering energy costs.

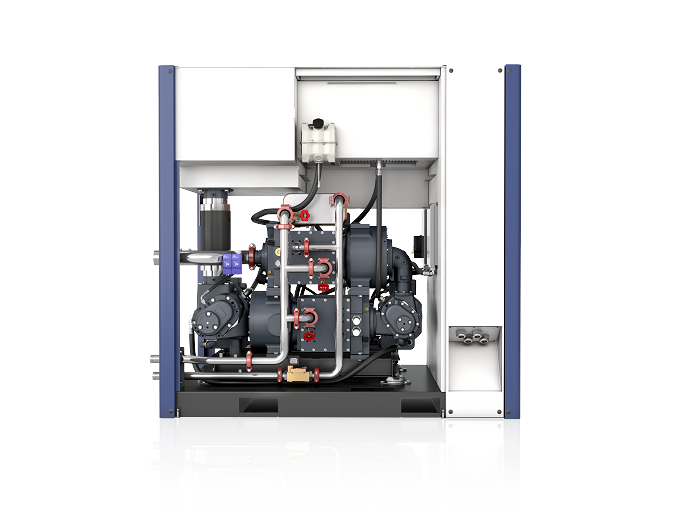

Space-Saving, Compact Design

With a 34% smaller footprint than its predecessor and up to 50% smaller than competing models, Ultima maximises valuable floor space while delivering powerful performance.

Direct-Drive, Gearbox-Free Technology

A fully integrated airend-drive system removes the need for a gearbox, reducing friction losses, wear and tear, and overall maintenance needs.

Advanced Heat Recovery for Cost Savings

All models support heat recovery – producing hot water up to 90°C, allowing industries to reuse waste heat for process heating, water heating, and facility warming, dramatically cutting operational costs.

Whisper-Quiet Operation

Ultima creates a quieter working environment designed for ultra-low noise levels, making it ideal for noise-sensitive applications.

Smart Digital Control & Remote Monitoring

The intuitive Delcos XL SE7 Controller provides a real-time overview of compressor performance, remote connectivity, and predictive maintenance insights—enhancing uptime and efficiency.

Eco-Friendly Powered Breather System

Ultima’s advanced oil mist separation technology prevents emissions into the atmosphere, ensuring a cleaner work environment and reducing oil consumption.

Future-Ready Power Upgrades

Ultima can be scaled up with on-demand power upgrades as your business grows, eliminating the need for costly additional compressors.

Multiple energy saving dryer options

For lowest pressure dew points – e.g. Subfreezing, Drum dryer, HOC.

Comprehensive Service & Predictive Maintenance

Built-in iConn connectivity provides proactive service alerts and real-time system monitoring powered by Ecoplant, minimising downtime and ensuring continuous operation. Ultima: Performance, Reliability, and Sustainability – All in One!

The unique drive design

Traditional oil-free compressors are driven by a single motor using a gearbox which in turn, drives both the low and high pressure airends. Gearboxes require oil and create friction which equates to energy loss. Ultima uses ultra high efficiency motors which replace the gearbox and the single motor which optimise performance throughout the complete volume range, as the airends can be driven at different speeds dependant on the demand. With a single motor driving both airends together this is not possible. This is where Ultima is hard to beat. The Ultima design utilises an intelligent “digital gearbox” design which continuously monitors and independently adjust the speeds of each airend, ensuring maximum efficiency and pressure ratios at all times. When any regulated speed compressor gets to the minimum speed, it goes into idle run. For any compressor, this is wasted energy. Ultima uses 45% less energy in idle run than a conventional two-stage compressor and a 160kW compressor uses only 8 kW in idle run.Even greater efficiency

- Regulated speed compressors go into idle run at minimum speed, wasting energy

- Ultima uses 45% less energy in idle run compared to conventional two-stage compressors

- A 160kW Ultima compressor uses less than 8kW in idle run

In-Built Power Upgrades

- Much cheaper than an investment in new or additional compressors

- No waiting period for build and delivery

- No downtime for installation and commissioning