Project Description

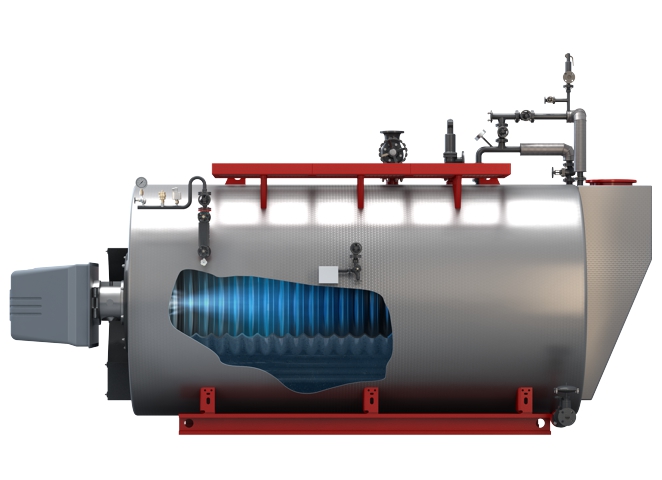

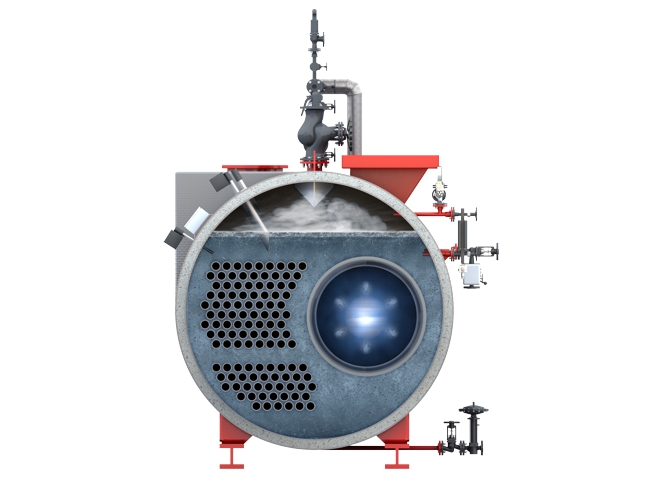

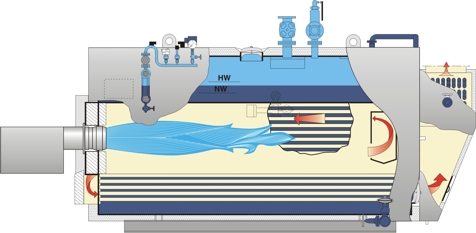

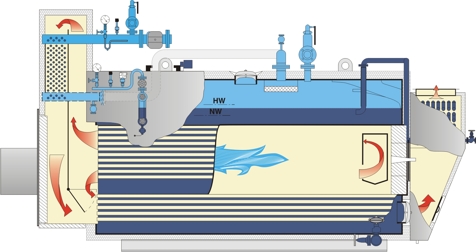

The flame tube, internal water-flushed rear flue gas reversing chamber, first smoke tube and second smoke tube are all arranged for optimum flow within the cylindrical pressure vessel. In interplay with one another, the radiant and convection heating surfaces promote rapid water circulation, thereby accelerating the passage of steam bubbles to the steam chamber. The heat supplied by the fuel is converted into steam quickly and with no material stress due to an even transfer of heat. The large water chamber offers sufficient storage volume to be able to accommodate sudden peaks in demand.

| Type | UNIVERSAL UL-S | UNIVERSAL UL-SX |

|---|---|---|

| Heat transfer medium | High-pressure saturated steam | High-pressure superheated steam |

| Design | Three-pass single-flame tube/smoke tube technology | Three-pass single-flame tube/smoke tube technology |

| Output | 1,250 to 28,000 kg/h | 2,600 to 28,000 kg/h |

| Safety pressure | up to 30 bar | up to 30 bar |

| Max. temperature | to 235 °C | to 300 °C |

| Fuel | Oil, gas | Oil, gas |

UL-S steam boilers are mainly used in the processing industry, in the commercial sector and in public facilities.

- Intuitive PLC-based boiler control with very high operating data transparency

- High level of efficiency due to three-pass technology, integrated economizer and effective thermally insulating materials

- High level of pressure consistency and steam quality even with widely fluctuating steam demand

- The boiler can be equipped with a separate fourth pass in order to exploit waste heat

- The boiler body can also be used as a pure waste heat boiler downstream of combined heat and power units or gas turbines

- SUC automatic start-up, standby and shutdown control

- Suitable for all burner systems

- Pollutant reduced combustion thanks to the use of highly developed firing systems and careful selection of the best boiler and burner combination

- Easy commissioning with pre-parameterised boiler control

- Easy wiring on site thanks to plug-in connections

Our three-pass patent dating from 1952 forms the basis for the outstanding and ongoing success of this series. The flame tube (first pass) and two smoke tube bundles (second and third pass) are integrated in an ideal manner into the pressure vessel together with the water-flushed rear reversing chamber. The laterally positioned flame tube and the horizontal rear and vertical front heating gas reversal produce a large radiant and convection heating surface with a large steam chamber, but the external dimensions remain small. The floors are anchored stably by the large continuous flame tube and they are ingeniously connected with the boiler shell using gusset stays for even load distribution.

If superheated steam is required instead of saturated steam, a superheater module can be positioned on the front reversing chamber. A bypass valve constantly controls the temperature of the superheated steam over a large load range. The smoke tube areas remain easily accessible thanks to the pivoting door of the reversing chamber.

- Modular system, controlled on the flue gas side – no injection water required for temperature control of the superheated steam

- Easy maintenance and installation – simple cleaning of the second and third boiler pass

- Long service life thanks to low thermal loading of the heat exchanger bundle of the superheater

All of our shell boilers come as fully functional units inclusive of all equipment. The basic equipment includes the boiler pressure vessel, the control and safety technology, the burner unit, a pump module, a terminal box and the control cabinet including our easy-to-operate BCO boiler control.

Basic equipment

Variable according to customer requirements

Associated boiler house components:

- WTM water treatment module

- WSM water service module

- CSM condensate service module

- BEM blow-down, expansion and cooling module

- WA water analyzer

- ECO 1 Stand-Alone flue gas heat exchanger

- ECO 6 flue gas heat exchanger for condensing use

- EHM expansion and heat recovery module

- PM pump module

- EHB expansion, heat recovery and blow-down module

- VC vapour cooler

- GRM gas regulation module

- OCM oil circulation module

- OSM oil supply module

- OPM oil preheater module

- SCO system control