Project Description

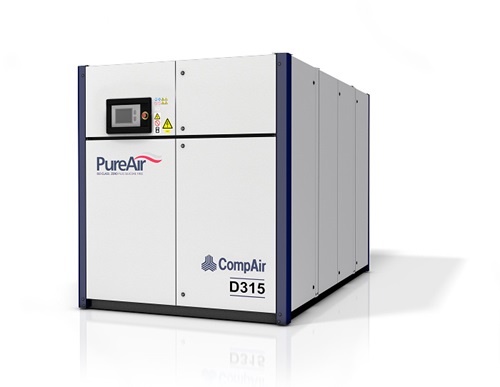

- Air purity that meets the most stringent hygienic standards

- Award-winning Class 0 Certified oil & silicone-free screw compressors

- High efficiency, low pressure losses, low temperature operation & economical control

The new models (from 160 to 315kW), which also utilise a CompAir designed and manufactured two-stage airend, offer oil-free and silicone-free air. No matter what industrial sector, there is a growing demand for higher quality, oil-free compressed air that meets the stringent quality standards. Whether it is needed for food and beverage or chemicals production, supply of pharmaceuticals, electronics or sensitive components, manufacturers will no longer accept the risk of product or equipment contamination. For this reason, CompAir’s D-Series offers the highest standard of air purity and has been certified ISO 8573-1 Class Zero (2010) oil and silicone free.

Guaranteed efficiency is provided by the excellent high quality IE3 or IE4 electric motor, along with legal conformity, high reliability and operational safety. These are great benefits in addition to automated motor lubrication. These oil free rotary screw compressors utilise two efficient radial fans in accordance with ErP Efficiency Legislation 2015, offering low noise levels, low pressure loss and excellent cooling performance.

Guaranteed efficiency is provided by the excellent high quality IE3 or IE4 electric motor, along with legal conformity, high reliability and operational safety. These are great benefits in addition to automated motor lubrication. These oil free rotary screw compressors utilise two efficient radial fans in accordance with ErP Efficiency Legislation 2015, offering low noise levels, low pressure loss and excellent cooling performance.

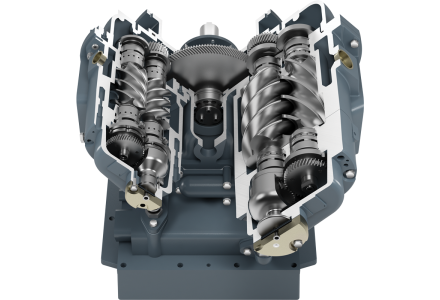

The closed water circuit for airend cooling achieves a constant low temperature level, also meaning that fewer gearboxes are required. The high output, two-stage airend design provides 100% oil-free and near isothermal compression with high reliability thanks to constant low temperatures, allowing use in demanding applications in up to 45°C ambient temperatures.

The sophisticated multilingual Delcos XL touch-screen controller protects your investment by continuously monitoring operational parameters. CompAir’s own designed and manufactured airend works at constant low temperature levels and lowers the compressor’s lifecycle costs. which is essential for reducing cost of ownership. The controller is very user friendly and yet, the integrated SD card allows for an in-depth analysis of monitored machine parameters. These parameters include:

- Optional base load sequencing

- Trend diagrams for Network pressure

- Motor speed (regulated speed models)

- On load hours / total running hours and average volume flow

- Weekly average volume flow

The high output, two stage airend design provides 100% oil-free and near isothermal compression with high reliability thanks to constant low temperatures, allowing use in demanding applications in up to 45°C ambient temperatures.

The high output, two stage airend design provides 100% oil-free and near isothermal compression with high reliability thanks to constant low temperatures, allowing use in demanding applications in up to 45°C ambient temperatures.

Guaranteed efficiency is provided by the excellent IE3 electric motor, along with legal conformity, high reliability and operational safety – great benefits in addition to automated motor lubrication.

Please watch this video to learn more about how the D series generates the oil-free air you need for your processes.

The compressors utilise two efficient radial fans in accordance with ErP Efficiency Legislation 2015, offering low noise levels, low pressure loss and excellent cooling performance. The closed water circuit for airend cooling achieves a constant low temperature level, also meaning that less gearboxes are required.

Delcos XL touch-screen controller

The multilingual Delcos XL control system ensures reliable operation and protects your investment by continuously monitoring the operational parameters, which is essential for reducing cost of ownership.

- Precise monitoring for exceptional operational reliability

- Ambient pressure and temperature

- Inlet and outlet pressure and temperature at both stages

- Network pressure and temperature

- Oil / water pressure and temperature

- Oil / water level

- … and many more

- High resolution, easy-to-use touch-screen panel

- User-friendly clear menu structure

- Integrated SD card for in-depth analysis of monitored machine parameters

- Optional base load sequencing

- Trend diagrams for

- Network pressure

- Motor speed (regulated speed models)

- On load hours / total running hours and average volume flow

- Weekly average volume flow