Project Description

A scroll compressor is also referred to as a spiral compressor, a scroll pump or a scroll vacuum pump. The rotary spiral scroll design creates a continual compressed air flow over multiple stages and there is no need for oil lubrication. A scroll compressed air system runs quieter and more smoothly than a reciprocating version because there are only two moving parts – a fixed scroll and an orbital scroll. Fewer parts make the scroll compressor energy efficient, highly reliable, and less prone to mechanical failure. Compared with a rotary screw compressor, a scroll compressor vibrates less and is almost noiseless.

- 100% oil-free design

- High reliability

- Continuous operation, 100% duty cycle

- Energy efficient

- Low vibration and sound levels

- Compact design

- Low maintenance due to less moving parts

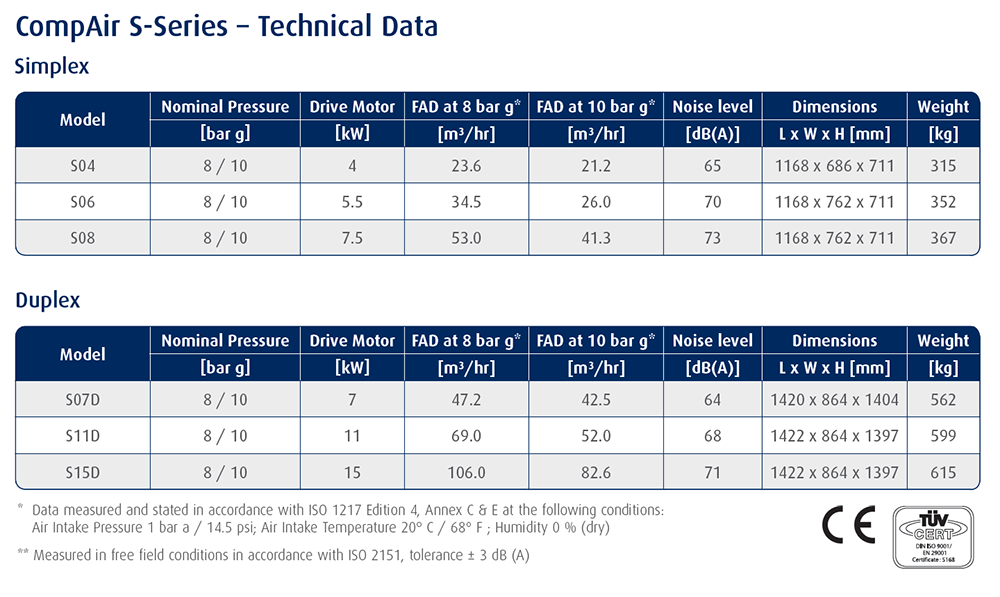

Simplex Models S04 – S08, with their small footprint, low noise level and vibration dampening construction, provide an efficient and oil-free smaller scale compressed air service.Duplex Models S7D – S15D are quiet models with maximum noise volumes reaching 72db(A). The Duplex systems offer high quality, oil-free compressed air services.Both the Simplex and Duplex models are available with the Deluxe HMI electronic controller. It is optional with Simplex but comes standard with the Duplex models. This powerful control and monitoring system gives you access to a variety of tools including alarm and fault logs, pump discharge temperature monitoring and a system capacity and operation trending meter among many others.The multi-lingual digital controller features a 3.5” full-colour screen that offers powerful navigation tools and intuitive data displays to makes the S-Series easy to control and monitor. The Deluxe HMI controller also features an integrated web server, allowing you to monitor the system from any computer, tablet or mobile device.With power options ranging between 4kW and 15kW, the S-Series offers the flexibility and guaranteed reliability to be suitable for a wide range of applications regardless of the conditions.

Simplex Models S04 – S08, with their small footprint, low noise level and vibration dampening construction, provide an efficient and oil-free smaller scale compressed air service.Duplex Models S7D – S15D are quiet models with maximum noise volumes reaching 72db(A). The Duplex systems offer high quality, oil-free compressed air services.Both the Simplex and Duplex models are available with the Deluxe HMI electronic controller. It is optional with Simplex but comes standard with the Duplex models. This powerful control and monitoring system gives you access to a variety of tools including alarm and fault logs, pump discharge temperature monitoring and a system capacity and operation trending meter among many others.The multi-lingual digital controller features a 3.5” full-colour screen that offers powerful navigation tools and intuitive data displays to makes the S-Series easy to control and monitor. The Deluxe HMI controller also features an integrated web server, allowing you to monitor the system from any computer, tablet or mobile device.With power options ranging between 4kW and 15kW, the S-Series offers the flexibility and guaranteed reliability to be suitable for a wide range of applications regardless of the conditions.

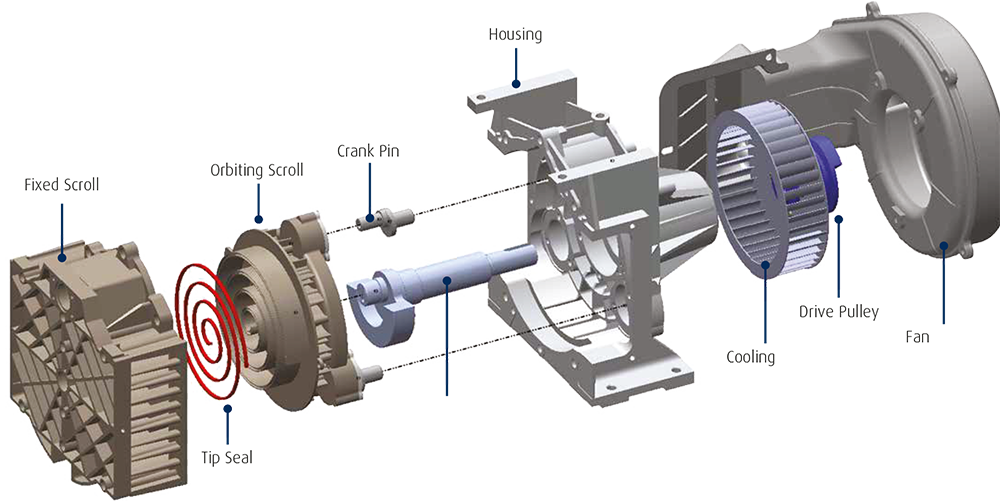

Scroll compression explained

- An orbiting (rotating) scroll and fixed scroll housing are mated to create the compression chambers.

- The continual movement of the orbiting scroll moves atmospheric air from the intake toward the center, compressing the air into progressively smaller areas.

- The compressed air is directed to the center discharge port of the compressor

- Discharge pressure is accomplished during multiple stages of compression, resulting in a continuous intake suction and discharge.

The S-Series from CompAir is available with different controller options. The Simplex versions can be either equipped with the basic relay panel or optionally with the Deluxe HMI electronic controller.

The S-Series from CompAir is available with different controller options. The Simplex versions can be either equipped with the basic relay panel or optionally with the Deluxe HMI electronic controller.

- NEMA 1, UL508A Labeled Panel

- Magnetic Contactor with Overload Protection

- 115V Control Circuit Transformer with Fusing

- Door Mounted TOA Switch

- Green Power On Light

- Emergency Stop

- Reset Button

- Run Time Meter

- Pressure Gauge

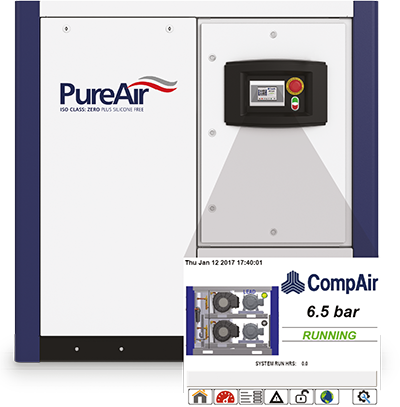

The optional Deluxe HMI control from CompAir has easy to use navigation and friendly graphics that deliver interactive and intuitive information at your fingertips.

With a built in integral webserver, via ModBus TCP Ethernet connection, these controllers provide visibility to the scroll compressor system from any computer or mobile device with internet connection.

Deluxe HMI

- 3.5” Full Color Touch Screen

- PLC Controlled

- Lead/Lag Control with Forced Alternation

- System Capacity and Operation Trending

- 26 Language Options

- 24VDC Power Supply with Fusing

- System Run Time Meter

- Alarm/Fault Log

- System Discharge Pressure

- Pump Discharge Temperature

- System Maintenance Timers

- Integral Webserver

- Modbus TCP Interface over Ethernet