Project Description

ROBOX Energy Series

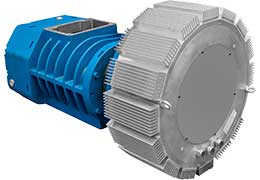

Screw Blower Package

ROBOX Energy Series

Maximum Energy Efficiency

Maximum Energy Efficiency

Superior pump technology, incorporating a permanent magnet motor fitted directly to the conductor shaft, with a wear-free design, prevents any potential loss of power from the belt drive and can realise energy savings of up to 30 per cent, compared to a standard rotary lobe machine.

Smart and Flexible

The Robox Energy screw blower is equipped with the latest generation (HMI) “touch screen” control panel. It is user-friendly with an intuitive menu, easy to program thanks to the well-known Windows CE system and can be remotely connected. The flexibility and versatility of the new Robox screw blower is masterminded by Robuschi’s Smart Process Control tool. It analyses and applies the oxygen data received directly from the process and adjusts the operating parameters accordingly without interrupting the process.

Extremely Compact

Robox Energy requires approximately 30% less space than comparable units. It responds to the growing market for smaller and compact machines in the compressor room. An other advantage of its design is the fact that several units can be placed next to each other with front access for the maintenance.

Connected

Connected

WATER 4.0 puts digitisation and automation at the centre of the industry strategy, aimed squarely at creating resource-efficient, flexible and competitive water management.

The new Robox Energy screw blower equipped with iConn module delivers just that.

iConn provides plant operators with in-depth and real-time data, essential for an optimised and efficient wastewater treatment operation. The remote availability of machine operation data saves time by removing the need for on-site supervision, optimises maintenance and parts management, and paves the way for the development of predictive models.

iConn optimises maintenance, maximises blower reliability and enables customers to focus on their core business.