Project Description

Oilless rotary screw technology 15-110kW

Oilless Screw Air Compressor

Oilless rotary screw technology 15-110kW (20-147hp)

Why oil-less? No Oil – No Risk

If 100% clean and oil-free compressed air is a requirement for your industry, you cannot compromise on quality. These water-injected screw compressors are available in water-cooled and air-cooled versions and are ISO 8573-1 CLASS 0 certified. Offering not only 100% pure oil-free air but also improved energy efficiency, these compressors are made to meet the precise needs of a diverse range of industries.

Advanced totally oil-free technology

Advanced totally oil-free technology

The ISO 8573-1 CLASS O certified EnviroAire T compressors offer the following benefits:

- 100% silicone-free, guaranteed

- Specifically designed for use in pure-air critical applications

- Avoids contamination and provides the highest air quality standards

- Independently tested and certified

For many industries such as ‘food & beverages’, ‘pharmaceuticals’ and ‘electronics’, air purity is a critical factor where even the smallest drop of oil risks contamination that can have severe consequences such as:

- Product spoilage

- Production downtime

- Damage to production equipment

- Damage to brand reputation

Your Benefits at a Glance

- 100% oil-free

- High quality electric motors

- Fully integrated silenced package

- Single-stage, direct-driven drive maximises efficiency and minimises maintenance

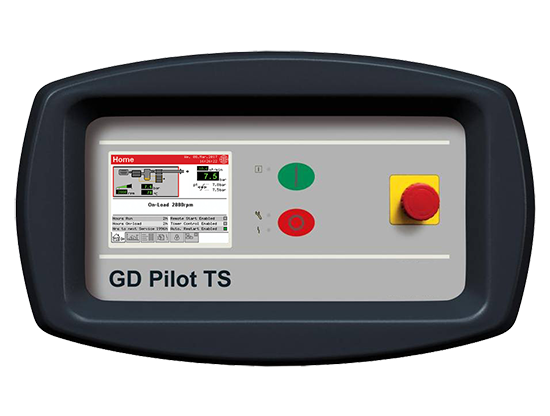

- State-of-the-art “GD Pilot TS” touch screen controller

- High quality water injection lubricates, cools and seals the compression process, maximising efficiency

- Easy service arrangement

|

|

100% oil-freeLow operating temperatures and bearing loads enable maintenance free sealed bearings to be used, totally removing the need for lubricating oil in the compressor. 100% oil-free compression is therefore guaranteed and the maintenance and environmental costs associated with oil and oil filter changes are eradicated. |

|

|

Single stage. Water injected air-endHigh quality electric motorsGD Compressors use the highest quality electric motors available, to ensure high quality and premium efficiency. |

|

The VS variable speed compressor – one smart solutionThe VS compressor is an efficient and versatile solution even for the most demanding industrial applications and carries all of the Gardner Denver features and benefits associated with reliable, easy to use operations and high efficiency. |

State-of-the-art “GD Pilot TS” touch screen controller – everything under control

The “GD Pilot TS” with its high resolution touch screen display is extremely user-friendly and selfexplanatory.

All functions are clearly structured in five main menus and are intuitively visual. The multilingual “GD Pilot TS” control system ensures reliable operation and protects your investment by continuously monitoring the operational parameters, which is essential for reducing your running costs.

With the ability to display detailed system analysis in the form of trend diagrams and graphs, operating parameters can be precisely set to maximise the efficiency.

- Line/network pressure

- Motor speed (variable speed)

- On load hours/total hours run & average volume flow

- Weekly average volume flow

- Ambient pressure & temperature

- Inlet/outlet pressure and temperature at both stages

- Oil/water pressure and temperature average volume flow