Project Description

MAG-11

Magnetically operated zero air loss drain

FEATURES

| Two inlet options. |  |

|---|---|

| Incredible compact design. |  |

| Direct acting valve, for a reliable discharge. |  |

- Extremely compact with top and side inlets.

- Easy to install in tight locations.

- No electricity required and no operating cost once installed.

- Level sensed magnetic technology saves air, energy and money!

- 2/2-Way direct acting valve, for a reliable discharge of virtually any condensate.

- Rugged corrosion resistant aluminium housing finished with an ElectroPhoretic coating.

- Lightweight, yet strong and durable.

- Built in air lock prevention.

- Service kits available.

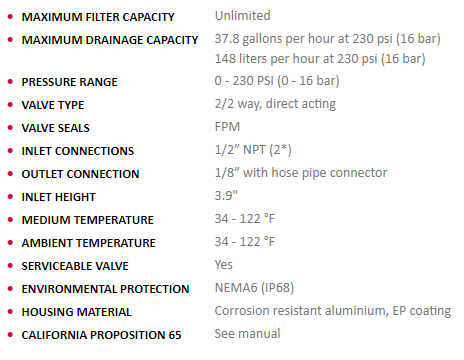

- Operating pressure 0 to 230 PSI.

- Bottom (outlet) can be rotated 360° for installation simplicity.

The MAG-11 is the optimum choice in compact energy saving condensate drains, typically installed in (refrigerated) dryers and under piston compressors.

Unlike timer or electronic drains, which require electricity to operate, the MAG-11 operates using a magnet level sensor providing energy saving zero air loss operation without the need for a power source.

Perfectly suited for coolers, refrigerated dryers, liquid separators and piston compressors, the MAG-11 uses a magnetically operated 2/2-way direct acting valve assembly, discharging the condensate from your compressed air system without losing any of your valuable compressed air.

The MAG-11 meets the demand of virtually any application, regardless of the condensate flow. It fits in any application, regardless of size, without any set up or adjustment.