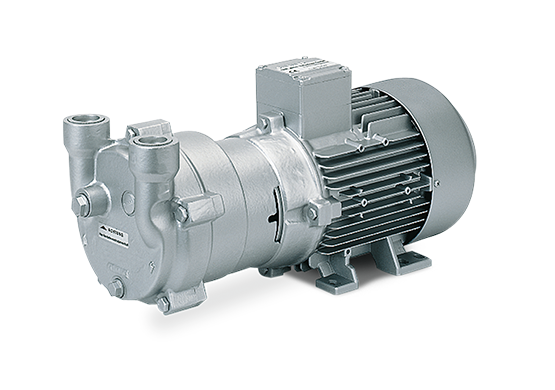

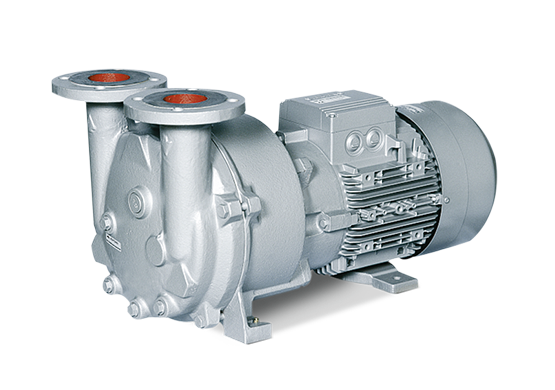

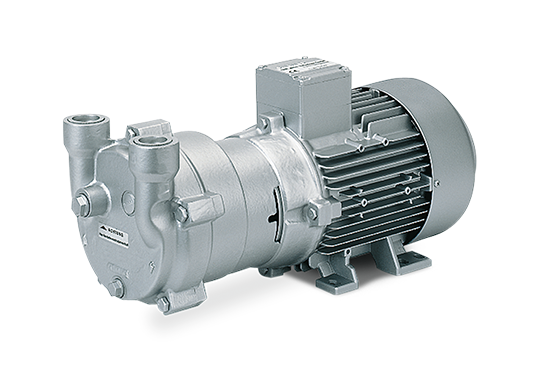

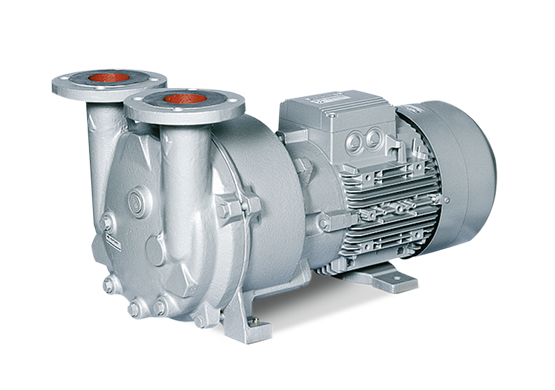

Project Description

Extreme conditions, which prevail in humid and wet processes, lead to lime scale or abrasion, and hence to a considerable reduction in the performance of the pump. Elmo Rietschle liquid ring pumps, however, meet these challenges.

The use of high-quality materials such as stainless steel and ceramics ensure utmost reliability and constant operating characteristics – for years to come.

Choose The Right Air Compressor - Oil Free or Oil Less

When it comes to choosing between an oil free air compressor or an oil less air compressor, you have both options from Gardner Denver. Gardner Denver oil free and oil less compressors feature cutting edge technology and are highly engineered product that result in pure, quality compressed air.

Oil free compressors have no oil present within the compression chamber. Oil less compressors contains no oil throughout the entire system, nullifying the risk of any oil leaking into the air.

Energy efficient compressors provide customers with low operating costs and mitigate the risk of contamination. No oil in the compression chamber minimizes downstream filtration requirements and pressure drops.

Some of the most common industries that utilize oil free or oil less compressors from food and beverage, pharmaceutical, electronic, healthcare, power generation and more. Models from Gardner Denver are ISO 8573-1 Class certified.

Oil Free Compressors Versus Oil Less Compressors: There’s A Difference

Does your application requires zero oil in your compressed air system? An oil less air compressor is what you need. Need a compressor without the risk of contamination within the compression chamber? The oil free air compressor is right for you.

For instances where the consequences of oil contamination is too high, oil free compressor technology is a must. If you are trying to achieve Class 0, which indicates zero oil present within the compressor, an oil less compressor is going to be best suited for your job.

Some of the key benefits of utilizing either an oil free or oil less air compressor include:

- Compliant with regulations - many industries, especially food and beverage and pharmaceutical, have strict regulations on compressed air.

- Reduction in maintenance costs with the lack of oil

- Reliability - produces high quality air

Some industries have developed extremely stringent quality standards. Within some applications, even the smallest contamination will cause product spoilage which can mean a significant loss of revenue and significant risk.

Lubrication in oil free compressors normally occur within the bearings and gears, which are completely isolated from the compression chamber so there is no risk of contamination. This is the case for both oil free rotary screw and rotary lobe compressors.

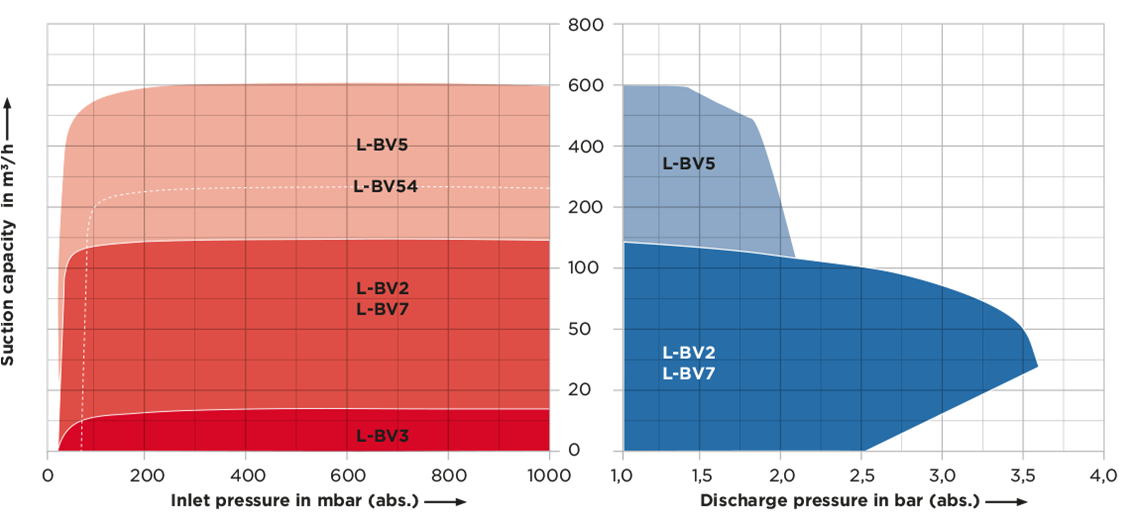

Air Map

Advantages at a Glance

- Constant operating characteristics by ceramic coating

- Maximum abrasion resistance

- Excellent corrosion resistance

- No deposits and lime scale