Project Description

This exciting new range of gear and direct drive compressors delivers up to 12% more compressed air with the same kW motor. The outstanding reliability makes these machines the preferred choice for large capacity applications.

Customers can gain maximum energy efficiency improvements with the new, premium efficiency inverter fitted in the RS variable speed machines, which can reduce running costs by up to 35%.

Engineering excellence

Compressors are more than just a financial investment,

they are a key component in ensuring that manufacturers,

processors and operators receive consistent, high quality, low cost air. The screw compression element is the heart of the compressor and therefore CompAir keeps the design and manufacture in-house, using the latest CNC rotor grinding machinery, coupled with online laser technology. The resulting reliability and performance ensure that operating costs will remain low throughout the compressors life.

Rotary Screw element

Rotary Screw element

The compact design of the compressor avoids unnecessary service costs. Therefore all components are designed for a long service life. A large oil cooler keeps the system temperatures low, lowers the pressure drop and enhances the oil, filters and seals life. The optimum cooling is achieved by a large surface after cooler and therefore provides low discharge temperatures. The proven airend delivers high performance and reliability.

Transmission Method – Direct Coupling

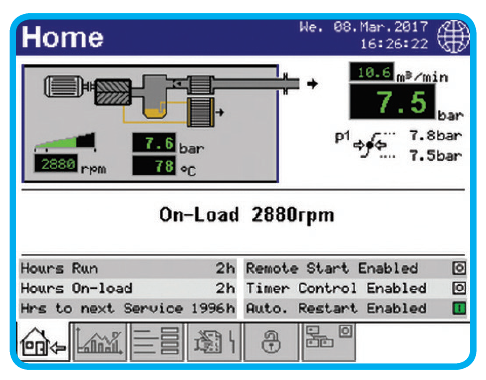

• Home Page – instant overview of the compressor status

• Real Time Clock – allows pre-setting of compressor starting/stopping

• Second Pressure Setting

• Integrated Cooling and Dryer Control

• Fault History Log – for in-depth analysis

• Remote Control via Programmable Inputs

• Auto Restart after Power Failure

• Optional Base Load Sequencing

• SD Card – stores several run characteristics

• iConn enabled

• Direct connection between four compressors by ( Delcos XL ) internal control without need to external control like other manufacturers of compressors