Project Description

Customized Power Plant Solution

Customized Power Plant Solution

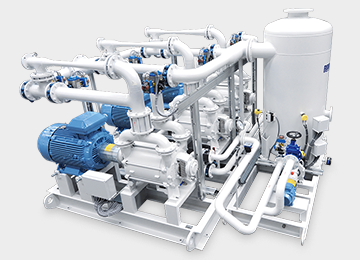

This is an air removal system in a power plant. The unit removes air and gas from the steam side of the condenser. It consists of three liquid rings vacuum pumps (RVS 40), mounted on a skid, including piping, valves, non-condensable tank separator, seal water cooler, controllers and ejectors for the first stage. All these components are controlled and monitored directly from the control room or through remote control.

The pumps are supplied with an ejector with bypass, in order to reach the requested operation conditions even with sea water as cooling liquid. Service liquid is cooled through a heat exchanger avoiding all contact contaminations between cooling and service liquid. A special alloy is used in the machine to validate its use with sea water as cooling liquid. The package capacity is 51 kg/h of saturated air at a pressure of 40 mbar and equipped with three motors of 55 kW.

Desalination Plant in Jebel Ali – Dubai

Desalination Plant in Jebel Ali – Dubai

In one of the largest desalination plants in the world in Jebel Ali in Dubai, which produces about 450 million cubic meters of drinking water per year, Robuschi supplied 4 customized liquid ring compressor units equipped with RVS 21 / SG pumps and special accessories: tanks with separator function, safety valve, automatic drain pump.

These units operate with a flow rate of 346 mᶟ / h and are used in the distillation process of sea water for the pumping of CO2 in the remineralisation phase.

Tailored Dry Solution for Mining

Tailored Dry Solution for Mining

This is a dry degassing group in ATEX II 2G configuration which includes rotary lobe blowers with pre-injection type “RB-DV”, operating as aspirators to remove the air – methane mixture from mining areas, allowing the mine to operate within the safety threshold. The blower RB-DV injection cooling system is provided by air – air exchangers.

There are 4 sizes of these types of groups, from 3,000 to 8,000 mᶟ / h of aspirated volume operating at vacuum up to 300 mbar(a). The groups include two blowers in parallel in order to ensure the reserve in any condition. In support of the group, on the suction line, there are separator cyclones and filters, arranged to keep traces of liquid, powder and solid impurities, which are often present in the mixture from underground mining basins.

Customized Degassing Unit for Mining

Customized Degassing Unit for Mining

This is a liquid ring compressor degassing unit in ATEX II 2G configuration, equipped with RVS liquid ring compressors, functioning as aspirators, to remove the air methane mixture from mining areas, allowing the mine to operate within the safety threshold. The service liquid (water) cooling is ensured by air – air exchangers.

This configuration assures a capacity of 5,000 mᶟ/h with an operating pressure up to 200 mbar (a). The groups include two RVS 60 pumps in parallel, in order to ensure the reserve in any condition. In support of the group, on the suction line, there are separator cyclones and filters, arranged to keep traces of liquid, powder and solid impurities, which are often present in the mixture from underground mining basins.