Project Description

Buran Dryers

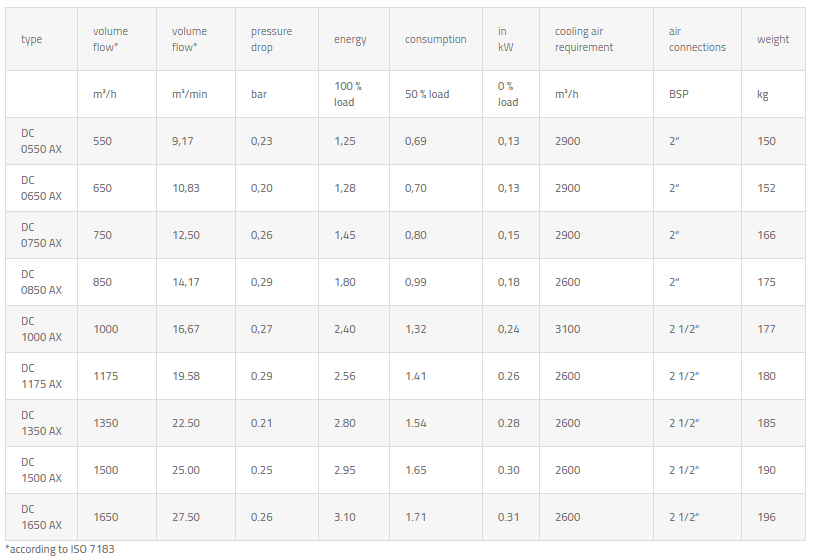

Flow From (9.17 m3/min – 27.5 m3/min)

Refrigeration Compressed Air Dryers for volume flows from 0550 to 1650 m³/h

The compressed air is being fed into the dryer and being pre-cooled in the air-to-air heat exchanger by the outgo- ing cold compressed air. The pre-cooled air then passes through the refrigerant-to-air heat exchanger where it is being cooled further down to the required pressure dew point. The moisture in the compressed air condenses out and gathers and discharges automatically. Finally, the cold discharged air is being reheated by the the incoming com- pressed air. This saves energy and prevents any moisture forming beyond the dryer in the compressed air system. The cooling capacity of the refrigeration cycle is being controlled by a microprocessor based controler to realize energy savings of up to 90 % and to assure the full dryer functionality for partial loads, too.

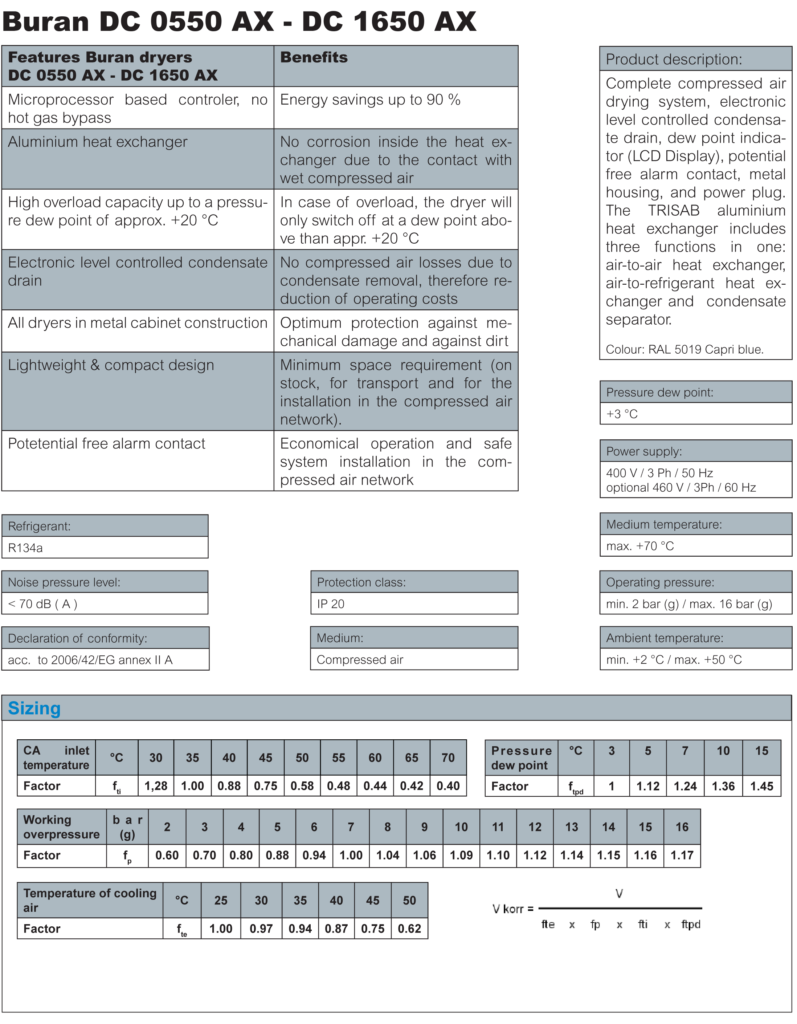

Buran DC 0550 AX – DC 1650 AX

Product description: Complete compressed air

drying system, electronic level controlled condensa- te drain, dew point indica- tor (LCD Display), potential free alarm contact, metal housing, and power plug. The TRISAB aluminium heat exchanger includes three functions in one: air-to-air heat exchanger, air-to-refrigerant heat ex- changer and condensate separator.

Colour: RAL 5019 Capri blue.

• An intelligent energy saving solution with reductions of up to 90%

• High overload capacity up to 20°C dew point under pressure

• Compressed air input temperatures up to a maximum of +70°C

• Compact construction

• One-of-a-kind TRISAB heat exchanger concept

• Electronic level-controlled condensate separator

• Potential-free fault messaging for secure integration in the compressed air network